Mob:+86-18671245438

Tel:+86-551-67707060

Micro-power electromagnetic brake with electromagnetic brake solenoid brake power stepper motors 24VDC electromagnetic brake

1.Application

The TQMB1 Series brakes is fricative braking device automatically set to working by a spring when a power-cut occurs.It's widely applicable in automatic door,stage apparatus,medical appliances,office facility,etc.,to secure a prompt and accurate braking effect. Because of its compact structure,lightweight,low noise and high reliability,it is widely accepted as an ideal piece of automation equipment.

USE

This series of electromagnetic power lost brakes are power solenoid pull-in, loses power, the spring loaded, achieve the friction brake, mainly for micro-motors, servo motors, stepper motors, electric forklift motors and other small light-duty motor. Applicable to metallurgy, construction, chemical industry, food, machine tools, packaging, the stage, lift, ship machinery, enabling rapid stopping, positioning accuracy, safety brake or other purposes.

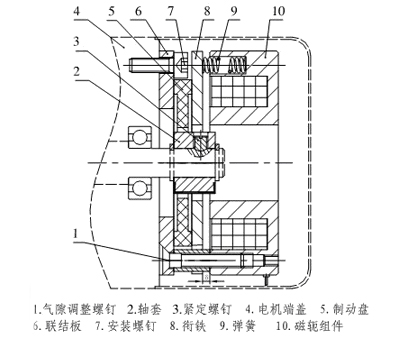

This series of brake yoke, the excitation coil, armature, springs, brake disc, composed of splines, manual release mechanism. After installing the motor end, adjust the mounting screws gas to the required value; on the spline fastened to the shaft, brake disc axial sliding of the spline sleeve, braking torque when braking.

When brake when the coil is energized, the coil creates a magnetic field, the armature is exhausted to the magnetic yoke and armature to disengage with brake disc, brake disc motor shaft turns with a normal; when the coil power, field, armature by spring force to the brake disc and friction torque and braking.

Flipping the "manual release device" or tightening "bolt release device", also can make the armature to release to facilitate equipment installation and adjustment. ;

This series brake work reliably under the following conditions

(1). work under dry conditions;

(2). in the surrounding medium, no explosion and no enough to corrode metal and damages insulation gases and conductive dust;

(3). working environment temperature -40~+150 ° c, friction plates and armature surface should grease must be kept clean;

(4). the insulation grade is b-class, degree IP23 voltage range up to +5% and 15%;

(5). the working air must not exceed maximum working air , brake master, slave side to be fixed, does not allow axial;

(6). installation: axis is vertically installed, install the brake must be guaranteed the same axle is not more than 0.1mm;

(7). operating mode: intermittent, continuous work.

2.Picture

3.Main Technical Data

| Item/Specification | TQMB1-0.5 | TQMB1-1 | TQMB1-2 | TQMB1-3 | TQMB1-4 | TQMB1-8 |

| Rated Torque(N.m) | 0.5 | 1 | 2 | 3 | 4 | 8 |

| Rated Power P20℃(W) | 9 | 9 | 10 | 12 | 20 | 25 |

| Rated Voltage(VDC) | 24/96 | 24/96 | 24/96 | 24/96 | 24/96 | 24/96 |

| Connecting Time(ms) | 45 | 50 | 55 | 60 | 63 | 87 |

| Disconnecting Time(ms) | 39 | 43 | 48 | 51 | 55 | 72 |

| Allowable Max Speed (rpm) | 5000 | |||||

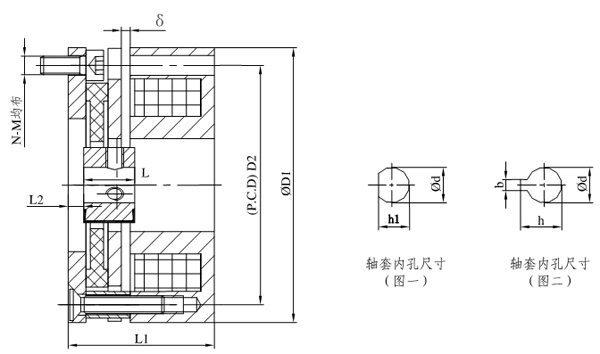

4.Chart and Dimension

| Size(mm) | d | D1 | D2 | L1 | L | L2 | h | h1 | b | M |

| Item | ||||||||||

| TQMB1-0.5 | 6 | 47 | 40 | 33 | 8 | 2 | 5 | 3xM3 | ||

| TQMB1-1 | 6 | 58 | 48 | 33 | 8 | 2 | 5 | 3xM3 | ||

| TQMB1-2 | 8 | 62 | 55 | 33 | 8 | 2 | 7 | 3xM3 | ||

| TQMB1-3 | 10 | 68 | 60.4 | 33 | 8 | 2 | 11.8 | 4 | 3xM4 | |

| TQMB1-4 | 12 | 82 | 72 | 35 | 10 | 2 | 13.8 | 4 | 3xM4 | |

| TQMB1-8 | 15 | 102 | 94 | 35 | 10 | 2 | 17.3 | 5 | 3xM4 |

5.Installation

Warning

Friction dirt and armature surface should kept clean and free of grease;

The air holes of all products hacek already had been adjusted,no more adjustment.

6. Examples for Installation

<li id="qqais"></li> .jpg)